Railways are the most used means of transportation. People prefer and enjoy train rides more than any other mode of transport; therefore, it is important for the railway authorities to take all the safety measures as they are the ones who have to ensure that everything is done perfectly in order to avoid any mishap. When it comes to railways, then extra attention need to be paid to the tracks, tracks are very important even a minute problem can cause a disaster. In order to maintain the condition of the railway tracks, track maintenance machines are there to take good care of the tracks. These machines are made in a way that they can easily repair or fix the tracks and can make them like they were before. There are many manufacturers who provide railway track machine at a very reasonable price. They also offer these machines at discounted prices in order to attract more customers. All the materials used by the manufacturers are of good quality so that people are not disappointed by them and prefer them again. They also have a sense of responsibility that induces them to work harder and manufacture standard machines for the individuals who visit them.

Railway Track Maintenance Machines:

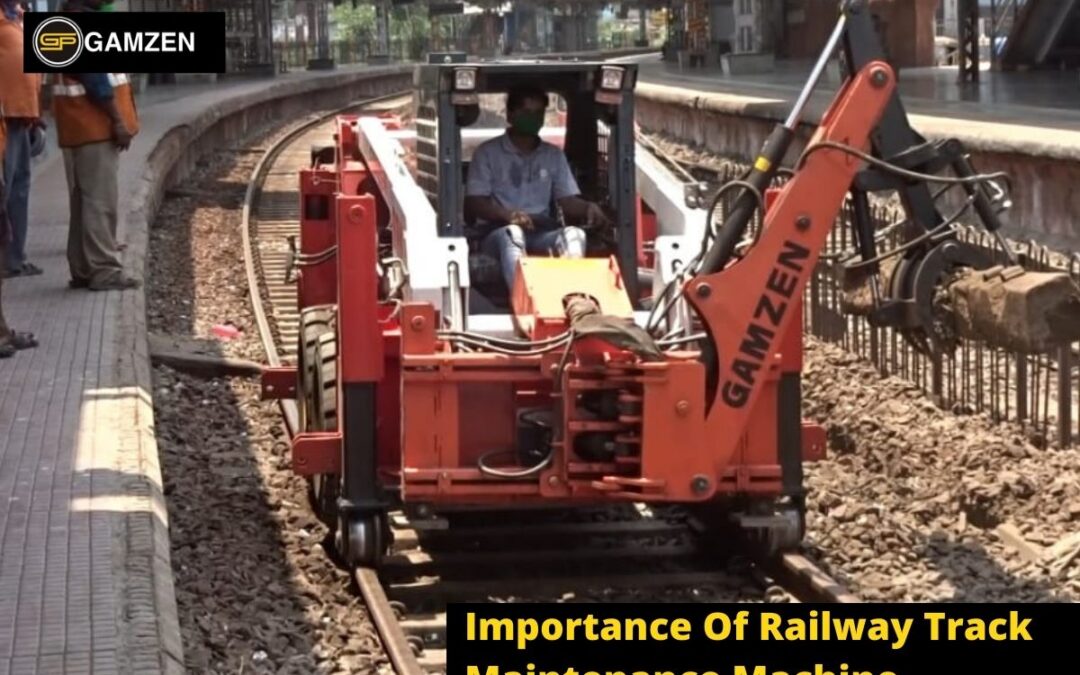

When it comes to railway maintenance machines then there are many machines that are used for different purposes. Some are good for cleaning the railway tracks and some of them come into use for other work related to railway tracks. With the advancement of technology, more machines are coming up in order to ease the work of the people. Gamzen track maintenance machine is one of them. This machine comes into use in many ways. It not only ensures operational safety and security but also helps in monitoring the maintenance of railway tracks. It helps in lifting up the sleeper and packs the ballast underneath. Other than the common functions like repairing and cleaning, there are several other functions that are performed by this Gamzen maintenance machine which include a slipper replacement, slipper handling, ballast handling, track handling, track lifting, and much more.

Why Track Maintenance Machines Are Important?

People love to travel by train but most of them fail to understand the importance of track maintenance. Maintaining the railway tracks is very crucial as there are many trains carrying people and an abundance of goods that pass by these tracks and one incident can ruin everything. Also, the tracks are exposed to various climatic conditions that cause the tracks to get damaged easily therefore, it is important that the railway tracks are maintained and are repaired from time to time. In order to maintain these tracks, railway maintenance machines play a very significant role. These track machines make impossible tasks possible and help to complete the work in a better and efficient manner.

Some points that highlight the importance of these machines are:

1. Ensure Safety:

If the machines are at work then the person is sure of the safety. The maintenance machine is used to maintain the tracks and to give assurance to the workers that the tracks are in a condition that a train carrying goods and precious lives of people can pass through it easily without any problem.

2. Rapid Completion Of The Work:

Machines are made so that the person does not have to spend hours in completing a particular task. Maintenance machines help to complete the task in a speedy manner. The work is completed way before the person was expecting it to get completed.

3. Work Becomes Simpler And Easier:

When the work is simple and easy then the person enjoys doing the work and is more enthusiastic about it. A railway track machine helps the workers to complete the task easily and in a more effortless manner.

4. Saves Time And Energy:

Taking care of the railway tracks and repairing them whenever needed is a complex task. It takes a lot of energy for the individual to complete this hectic task. But with the invention of machines, it is manageable for the workers to complete the task and it saves a lot of their time too.

These points clearly tell the significance of railway maintenance machines. These points explain why these machines are important for the people and what all benefits do these machines provide to the people who are using it. These machines are of great help to the people for who maintaining railway tracks the primary task is or who are dependent on this work for their day to day living.

How Railway Tracks Can Be Maintained:

The task of maintaining railway tracks is assigned only to the skilled people as it is not a cup of tea for everyone. There are many technicalities and conditions that are necessary to be kept in mind while doing this job. Several railway tracks machines contribute their part in this. There are some points that are of utmost importance and it needs to be completed very carefully with full concentration and dedication by the workers who have been assigned the work of maintaining the railway tracks.

These points are:

1. Grinding The Rail:

This sounds to be easy but it is actually not. There is a specific machine that is involved in the completion of this work. This work is done to correct the metal flow and re-profile the rail.

2. Replacing The Rail:

In simple words, it means upgrading or replacing the track. A new track is replaced with the old one. This is done as the old track gets defected due to the natural calamity, changing weather conditions, or any other major reason.

3. Tamping:

Tamping involves correcting the alignment of the tracks. Here the sleepers are lifted and put in an aligned way and inserted into the ballast.

4. Stabilizing The Tracks:

This step itself reflects the importance and the usefulness of performing it. After everything is done the tracks are stabilized in a particular direction for controlled settlement. It can help in reducing the lateral resistance therefore it needs to be done under the vigilance of an expert.

5. Blowing The Stones:

This process is done so that the longitudinal profile is in the correct manner. More stones are added to the existing ballast bedand the stable and compact ballast bed is left undisturbed.

6. Replacing The Sleeper:

When the sleeper gets defective then there is no alternative left but to change or replace the old sleeper with the new one. People cannot afford to take the risk as the rail can lose the correct gauge.

These were some of the points that explain how railway tracks can be maintained. It is very much clear with this that if any of the steps are not done properly then what can be the consequences. Anything can happen and to prevent any disastrous event, following these steps in a correct manner is very important. These points also signify the usage of machinery in completing these tasks. These tasks cannot be completed easily until and unless the latest and correct machinery is being used there for a track maintenance machine is equally important.